Hello, welcome to the website of Dongguan Guanwei Trading Co., Ltd.!

Guangwei Trading offers affordable and dependable

chemical raw material procurement solutions.

Hello, welcome to the website of Dongguan Guanwei Trading Co., Ltd.!

Guangwei Trading offers affordable and dependable

chemical raw material procurement solutions.

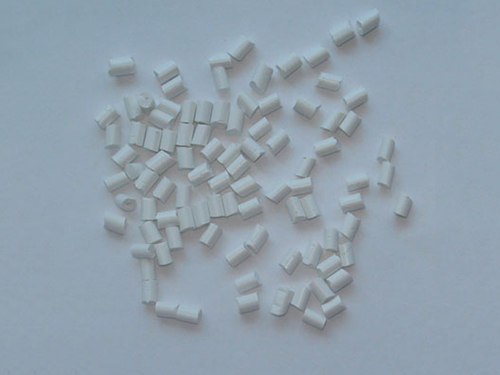

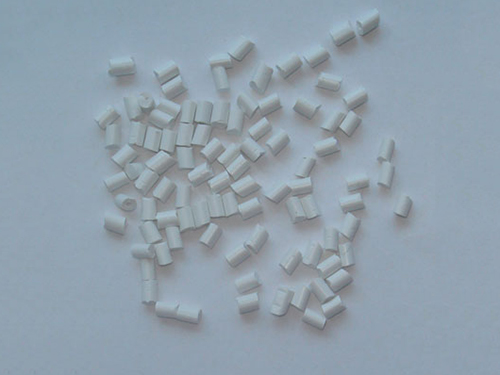

The synergistic flame retardant is made of silicon, tin and other composite products, which have synergistic flame retardant and auxiliary anti-drip effects, and the appearance is white powder. The application of the product in the antimony halogen flame retardant system can effectively replace part of the amount of antimony trioxide, improve the oxygen index of the material, and the overall performance of the polymer after the replacement can be kept intact, which is beneficial to improve the burning test of the material. The product has passed the EU ROHS/REACH certification. Does not contain heavy metals.

Flame-retardant mechanism

(1) Mechanism of gas phase flame retardant: The metal ion active ingredients and halogen-based flame retardants in this product act to increase the hydrogen halide reaction and release more effective flame inhibitors - metal halides. When viewed under a microscope, the metal compounds in the material changed the carbon's appearance, making it bright and crack-free. These changes enable the carbon layer to have better insulating properties, thereby improving flame retardancy.

(2) In the flame retardant process, the heat absorption is large, which is conducive to reducing the high temperature generated during combustion; a large number of experiments and applications have proved that the flame retardant effect of this product mixed with bromine antimony is better than that of pure bromine antimony. Better, the mechanical properties are improved, the oxygen index is increased, and the droplet property is reduced.

Product features: stable performance, strong versatility, non-toxic, smoke suppression, low cost.

Product use: Mainly used in modified engineering plastics such as PA, PBT, PET, PP, PE, ABS, PS, etc., PVC, wire and cable materials, rubber, foam materials, wire materials, coatings and other industries.